Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

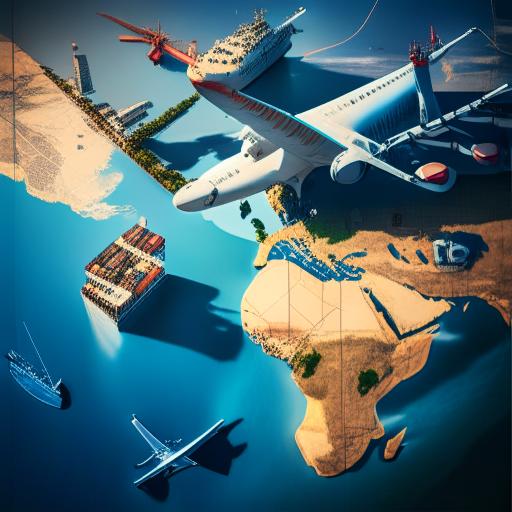

A Global Distribution Strategy (GDS) is a comprehensive plan that outlines how businesses transport products to customers across the world. The goal of a GDS is to achieve optimal logistics and transportation efficiency while ensuring excellent customer service. This involves coordinating a complex network of carriers, warehouses, and distribution centers operating across different countries, time zones, and legal systems.

In a world of increasing globalization and e-commerce, having an effective GDS has become crucial for businesses to succeed and stay competitive in their respective markets.

There are several reasons why a well-structured Global Distribution Strategy is essential for businesses. Some of the key reasons include:

Market Expansion: An effective GDS allows businesses to expand their market reach and tap into new customer bases, providing a substantial advantage over competitors who operate only within a limited geographic region.

Operational Efficiency: A successful GDS optimizes the flow of goods and services across borders, leading to faster delivery times, better inventory control, and reduced transportation costs. This, in turn, helps businesses improve their bottom line and overall profitability.

Risk Management: Global distribution networks across multiple geographic regions can help businesses navigate uncertainties, such as changing trade relationships, unexpected fluctuations in demand, or natural disasters.

Customer Satisfaction: A well-functioning GDS is critical for providing customers with timely access to products and services. This enhances brand loyalty and customer satisfaction, which are vital for long-term success, as well as word-of-mouth and referral marketing.

Competitive Advantage: Companies that excel in managing their GDS can provide better service than their competitors and, at the same time, reduce costs. This allows them to gain a significant competitive edge in the market.

An effective GDS relies on several critical components to operate smoothly and deliver positive results for the business. The primary components include:

The impact of a GDS on the supply chain is wide-ranging and affects every aspect of a business's operations. Some of the most significant ways a GDS can impact a company's supply chain performance include:

Our upcoming sections will provide insights into the benefits of a strong GDS, tips for crafting a successful strategy, and guidance on partnering with a 3PL for your GDS. Don't forget to check out our resources on The Ultimate Guide to Order Fulfillment and Innovative Distribution Logistics Solutions to further enhance your understanding of the subject.

A comprehensive Global Distribution Strategy (GDS) consists of several integral components that work together to streamline your supply chain. Understanding these elements will help you identify areas for improvement and keep your supply chain efficient.

Distribution channels: These channels, also called intermediaries, are the various paths your products travel to reach customers. Identifying and selecting the right distribution channels are crucial for efficiency and cost savings. These can include wholesalers, retailers, direct sales, and e-commerce.

Inventory management: Proper inventory management ensures a smooth flow of goods along the supply chain. It involves forecasting demand, setting stock levels, replenishing stock, and managing obsolete or excess inventory. Accurate inventory management reduces warehousing costs and improves cash flow.

Order processing and fulfillment: Your GDS should outline how orders are processed, assembled, packaged, and shipped efficiently. Your order management system should be integrated with your inventory management system to minimize errors and avoid stock discrepancies.

Transportation and logistics: This involves selecting the most cost-effective and efficient methods of transporting goods to distribution centers and end customers. Factors to consider include mode of transportation, carrier selection, and routing decisions.

Warehousing and storage: Strategically positioning warehouse locations can help optimize response times and minimize transport costs. Warehouse design, layout, and storage also play a vital role in the overall efficiency of your GDS.

Global trade compliance: Compliance with international trade regulations is essential in a global distribution strategy. This includes customs documentation, product classification, tariffs, and other relevant trade laws.

A well-developed GDS has a profound impact on the supply chain and overall business operations. Here's how it creates an efficient and seamless flow of goods across the distribution network.

Increased visibility: By having an organized GDS, businesses can track their inventory and shipments throughout the supply chain. This increased visibility reduces errors, improves responsiveness, and allows for better decision-making.

Enhanced customer experience: An optimized GDS results in faster delivery times, accurate order fulfillment, and improved communication with customers. This leads to higher customer satisfaction, increased brand loyalty and sales.

Reduced costs and increased efficiency: Leveraging economies of scale, streamlining processes, and optimizing transportation and warehousing are key benefits of a well-crafted GDS. These measures lead to cost reduction, operational efficiency, and ultimately, increased profitability.

Risk mitigation: An effective GDS helps businesses anticipate and respond to potential disruptions in the supply chain, such as increasing tariffs, changing regulations, and natural disasters. This proactive approach can minimize potential risks and keep business operations running smoothly.

Competitive advantage: By having a robust GDS in place, businesses can improve their market reach and scalability. This flexibility makes it easier to enter new markets, diversify product offerings, and adapt quickly to changing market conditions, giving companies a competitive edge.

In conclusion, understanding the key components that make up a Global Distribution Strategy and its impact on the supply chain is crucial for businesses looking to optimize their logistics and transportation processes. By doing so, your organization can unlock numerous benefits, such as improved customer service, greater efficiency, and increased profitability. To further enhance your GDS, consider partnering with a 3PL that can bring industry expertise and value-added services to your supply chain operations.

A strong Global Distribution Strategy (GDS) can provide many advantages for your business. This section will discuss some of the most significant benefits of having a robust GDS that is tailored to your organization's logistics and transportation needs.

One of the most critical benefits a sound GDS can offer is improved customer service. When your operations are efficient and well-planned, it's much easier to fulfill customer orders on time and with fewer errors. Some ways a robust GDS can improve customer service include:

Having an effective GDS ensures that products reach customers more quickly, leading to greater customer satisfaction. By strategically locating distribution centers and streamlining your supply chain, your GDS can provide more efficient routes for your shipments.

A well-designed GDS can improve order accuracy by minimizing errors in the picking and packing process. This can have a significant impact on your customers' satisfaction, as it reduces the chances of them receiving an incorrect product or incorrect quantities.

An effective GDS can facilitate better order tracking by streamlining the collection and sharing of essential information about shipments. This means that customers can access real-time information about the status of their orders, which can help to manage their expectations and build trust in your organization.

A robust GDS can greatly improve the efficiency of your entire supply chain. This can have a positive knock-on effect on other areas of your business, enabling you to offer improved products, services, and customer experiences. Some ways that a GDS can enhance supply chain efficiency are:

By meticulously analyzing demand patterns and employing a finely tuned distribution strategy, you can maintain optimal inventory levels without sacrificing the ability to fulfill orders. This prevents the costly problem of overstocking or stockouts, which can have significant financial implications for your business.

An efficient GDS can help to reduce overall logistics costs by improving transportation and warehousing efficiency. This can be achieved through better route planning, strategically located distribution centers, and eliminating redundancies in your supply chain.

Consolidating various supply chain processes under a single, coherent GDS can help reduce opportunities for disorganization and inefficiencies. This makes it easier for all members of the supply chain to work together and ensures smoother operations overall.

A well-implemented GDS can provide you with invaluable data analysis tools and capabilities, enabling better decision-making and forecasting. This can help you more accurately predict demand patterns, allowing for more informed decisions regarding inventory replenishment, distribution center locations, and transportation routes.

By enhancing customer service and supply chain efficiency, a strong GDS can ultimately lead to increased profitability for your organization. Some ways in which a GDS can contribute to greater profits are:

A GDS that helps you get products to customers more quickly, accurately and with greater order visibility is essential for driving sales. Happy customers are more likely to be repeat customers and recommend your products or services to others.

As mentioned before, a GDS can help lower logistics costs and reduce inventory-holding costs by optimizing stock levels, which in turn, can lead to increased profitability.

A GDS allows you to make more informed decisions on various aspects of your business, such as optimal pricing, placement, and promotion of products. This enables better resource allocation and ultimately leads to increased revenue.

In summation, developing an effective global distribution strategy can lead to substantial benefits for your logistics and transportation operation. From improved customer service and enhanced supply chain efficiency to increased profitability, a well-designed GDS can unlock the potential for significant growth and success. By carefully considering these benefits and tailoring your strategy to match your organization's unique challenges and requirements, you can position your business for long-term success in the world of logistics and transportation.

Crafting a successful global distribution strategy (GDS) is essential for businesses to maintain a competitive edge in today's fast-paced, interconnected world. This process involves assessing your current distribution network, identifying key areas of improvement, and developing a plan of action to optimize your supply chain. In this section, we will discuss the steps you need to take to create an effective GDS.

The first step in the creation of a successful GDS is evaluating your current distribution infrastructure. This comprehensive assessment will allow you to understand the strengths and weaknesses of your existing network, gain insights into the efficiency of your operations and ultimately, help you identify areas that require improvement. Here are some factors to consider during the assessment:

After assessing your current distribution network, you'll likely find areas that need improvement. These could be opportunities for cost savings, inefficiencies, or underperforming markets or channels. As a strategic decision-maker, you need to prioritize these improvement areas based on their potential impact on your supply chain performance and overall business objectives. Some areas to focus on include:

Once you've identified the key areas requiring improvement, it's time to develop a well-thought-out plan of action to implement these changes and optimize your global distribution strategy. This plan should contain clearly defined goals, timelines, and responsibilities to ensure that everyone involved is on the same page. Here are some steps to follow when developing your plan:

By following these steps and carefully crafting a global distribution strategy that takes into account the specific needs and objectives of your business, you'll be well-positioned to thrive in today's competitive market landscape. Remember, collaboration and adaptability are key: constantly reevaluate your GDS to ensure continued success and growth for your business.

In your quest to master global distribution strategy (GDS), it's crucial to understand the role of third-party logistics (3PL) providers, especially as you strive to expand your business globally. Embracing the services of a 3PL can positively impact your overall GDS, ensuring greater success and customer satisfaction. But how can you find the right 3PL partner? In this section, we'll delve into the reasons for partnering with a 3PL, the characteristics to look for in a good partner, and tips for selecting the best one for your business.

5.1.1 Access to a Global Network

As you enter the world of international logistics, a 3PL provider can grant you access to a worldwide network of resources, including warehouses, carriers, and technology, which would be difficult and costly to manage on your own. They can help you navigate complexities like customs regulations, shipping tariffs, and local delivery requirements. With their experience and resources, a 3PL smoothes the transition to global markets.

5.1.2 Cost Savings

Outsourcing your GDS aspects to a 3PL can reduce overhead expenses and streamline your operations. A well-established 3PL can negotiate better rates with carriers, allowing you to enjoy volume discounts and minimized risks of financial loss due to spoilage, excess inventory, or storage fees.

5.1.3 Scalability and Flexibility

3PLs can provide the flexibility your business needs as it expands and experiences fluctuations in demand, storage capacity, or delivery requirements. Their scalability allows you to efficiently adapt to market changes while maintaining high service levels.

5.1.4 Technology Advancements

By partnering with a 3PL, you gain access to advanced technology and systems that can optimize your GDS. With their investment in warehouse management systems (WMS), transportation management systems (TMS), and inventory management systems (IMS), 3PLs provide real-time insight, analytics, and visibility across your entire supply chain.

5.2.1 Proven Expertise and Experience

You want a 3PL partner with a track record of success in managing GDS. Look for provider that demonstrates understanding of your industry, familiarity with worldwide customs regulations, and a history of overcoming challenges in global distribution.

5.2.2 Strong Communication and Transparency

A 3PL that provides open communication and detailed reporting is crucial in keeping you informed on your supply chain's performance. Transparency enables you to make informed decisions and build trust between you and your 3PL.

5.2.3 Technology Integration

A good 3PL partner should be able to integrate their technology with your existing systems, ensuring seamless data flow across your entire organization. This is vital for maintaining visibility, tracking performance metrics, and reducing errors in your supply chain.

5.2.4 Commitment to Continuous Improvement

A 3PL partner should share your goals for continuous growth and improvement, working with you to optimize your global distribution strategy. By regularly reviewing performance data and suggesting improvements, they demonstrate a dedication to helping you succeed.

5.3.1 Define Your Needs and Goals

Before searching for a 3PL partner, clearly outline your objectives and specific needs, such as warehousing, transportation, or technology solutions. This assists in narrowing down your search and provides a solid foundation for 3PL evaluation.

5.3.2 Conduct Thorough Research

Invest time in researching potential 3PL providers. Examine online reviews, case studies, and speak with other businesses in your industry to identify providers that excel in managing GDS.

5.3.3 Request Proposals and Compare

Request proposals from your shortlist of potential partners. By comparing pricing, services, and capabilities, you can objectively gauge the value each 3PL brings to your GDS.

5.3.4 Evaluate Customer Service and Responsiveness

The 3PL you select should prioritize customer service and meet your expectations in terms of responsiveness. Ensure their communication style aligns with your business values.

In conclusion, partnering with a 3PL can significantly enhance your global distribution strategy. By assessing your needs and conducting detailed research, you can find a partner that helps you optimize your supply chain and increase profitability, enabling your business to excel in the global arena. Remember, selecting the right 3PL is a long-term investment in your company's future – choose wisely and reap the rewards of a successful GDS.